PRODUCT

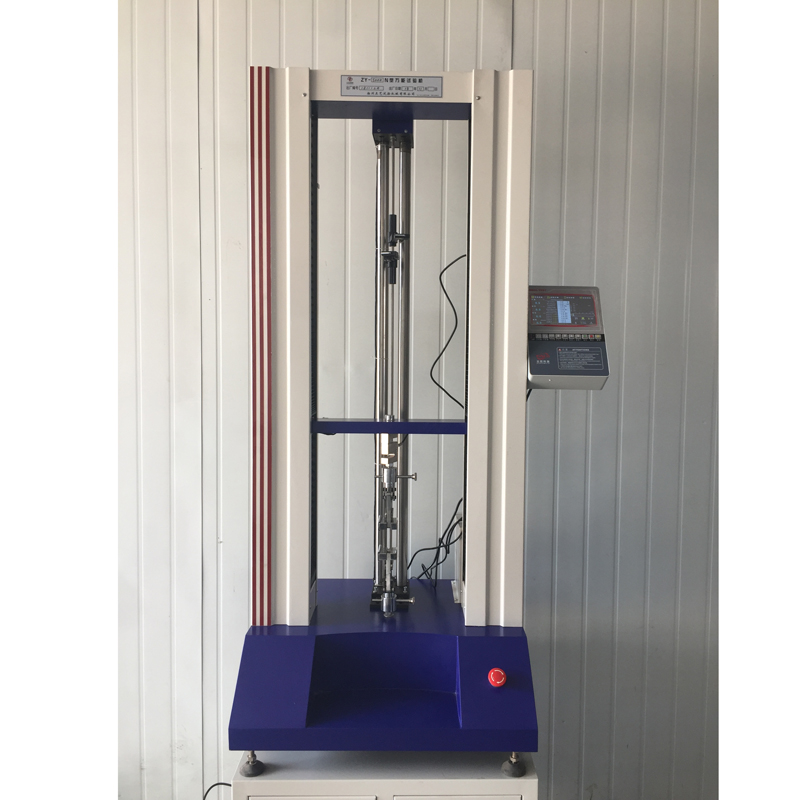

ZY-5000N plastic electronic tensile machine (double column digital display)

ZY-5000N plastic electronic tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

ZY-5000N plastic electronic tensile machine (double column computer)

ZY-5000N plastic electronic tensile machine can be used for rubber, plastic, foam material, plastic, film, textile, fiber, polymer material, composite material, synthetic material, packaging tape, paper, wire and cable, fiber optic cable, safety belt, leather Belts, shoes, tapes, polymers, spring steel, stainless steel, castings, non-ferrous metals, auto parts alloy materials and other non-metal materials and metal materials are stretched, compressed, bent, teared, 90° peeled, 180° Peel, shear, adhesion, pull-out force, elongation and other tests.

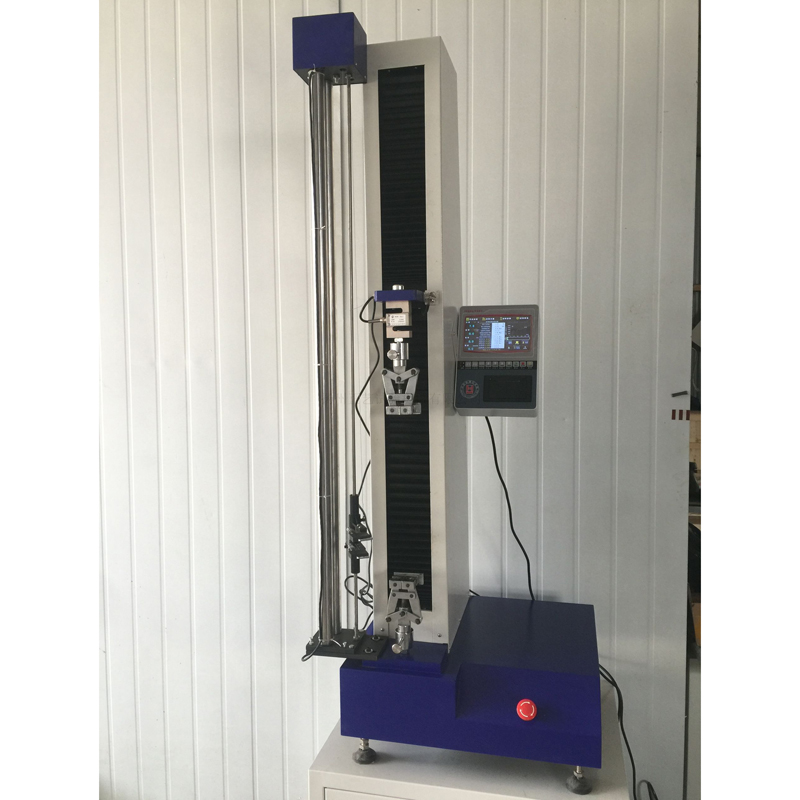

ZY-5000N plastic electronic tensile machine (single-column digital display)

ZY-5000N plastic electronic tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

ZY-5000N plastic electronic tensile machine (single column computer)

ZY-5000N plastic electronic tensile machine (single column computer)

ZY-5000N plastic electronic tensile machine can be used for rubber, plastic, foam material, plastic, film, textile, fiber, polymer material, composite material, synthetic material, packaging tape, paper, wire and cable, fiber optic cable, safety belt, leather Belts, shoes, tapes, polymers, spring steel, stainless steel, castings, non-ferrous metals, auto parts alloy materials and other non-metal materials and metal materials are stretched, compressed, bent, teared, 90° peeled, 180° Peel, shear, adhesion, pull-out force, elongation and other tests.

Host specifications

A. High-precision sensor: 5000N, the force accuracy is within ±0.5.

B. Capacity segmentation: Seven gears in the whole process: × 1, × 2, × 5, × 10, × 20, × 50, × 100, using high-precision 24 bits A/D, sampling frequency 200Hz, maximum power resolution 1/1000 ,000

C. Power system: high-precision closed-loop drive motor.

D. Control system: Use Pulse Command control method to make the control more precise. Speed control range 0.001~1000 mm/min. The linkage board adjustment has fast coarse adjustment and slow fine adjustment functions. After the test, it will automatically return to the origin and automatically store.

E. Data transmission method: USB transmission

F. Display mode: UTM107+WIN-XP test software computer screen display.

G. Concise linear double correction system for the first gear and precise seven gears throughout the entire journey.

H. The luxurious test interface software can realize constant speed, positioning shift, constant load (hold time can be set), constant load increase rate, constant stress increase rate, constant strain increase rate and other control modes, plus multi-level control modes can meet different requirements Test requirements.

I. Test space: Test width is about 380mm (standard specification), and the board walking space is 850mm (excluding fixture) (standard specification)

J. Full displacement: Encoder 2500 P/R, 4 times accuracy adopts LINE DRIVE encoder with strong anti-interference ability, displacement resolution is 0.001mm. K. Device: overload emergency stop device, upper and lower stroke limit device, leakage automatic power-off system, automatic break point shutdown function.

k. Manual control mode: manual operation box.

Software function:

A. Test standard modularity function: Provide users with the test standard settings required by the application, covering GB, ASTM, DIN, JIS, BS... etc. Test standard specification.

B. Sample data: Provide users with all sample data set by the user, and input the data once and use it repeatedly. The formula can be modified by itself to improve the fit of test data.

C. Double report editing: open user editing reports, for testers to choose their favorite report format (the test program adds a built-in EXCEL report editing function to extend the previous format of a single report)

D. The length, power unit, and display digits adopt dynamic interchange mode, power unit T, Kg, N, KN, g, lb, deformation unit mm, cm, inch.

E. Automatic Auto Scale of graph curve scale, which can make graph display in proper scale. And can switch dynamically in real-time graphics during testing. With load-displacement, load-time, displacement-time, stress-strain load-2 point extension diagram, and multi-curve comparison.

F. The test result can be output in the form of data in EXCEL format.

G. After the test, it can be automatically archived and manually archived. After the test, the maximum strength, upper and lower yield strength, hysteresis loop method, stepwise approximation method, non-proportional extension strength, tensile strength, compressive strength, and elongation strength at any point can be automatically calculated. , Any point fixed load extension, elastic modulus, elongation, peeling interval maximum, minimum, average, net energy, return energy, total energy, bending modulus, break point displacement x% load, break point load X% Displacement, etc. Data backup: test data can be saved in any hard disk partition.

H. Multiple languages switch randomly: Simplified Chinese, Traditional Chinese, English.

I. The software has a historical test data demonstration function.

The main technical parameters

1. Force resolution: 0.001-0.1N

2. System accuracy: less than ±0.1

3. Maximum test force: 5000N

4. Accuracy level: 0.5

5. Test force measurement range: 1-99%

6. Test force indication error: less than or equal to 0.3%

7. Test force resolution: 0.001

8. Displacement resolution: 0.001

9. Displacement indication error: less than or equal to 0.5%

10. Speed range: 0-500mm/min (special requirements can be customized)

11. The maximum stroke of the gripper: 800mm

12. Elongation tracking error: ±0.1mm

13. Power supply voltage: AC220V±10% 50Hz

14. Net weight: 150KG

Features

Automatic clearing: After the computer controls the test command, the system automatically clears;

High intelligence: After the test, the fractur

Previous page

1

Next page

Yangzhou Zhengyi Testing Machinery Co., Ltd.

Service Hotline:

Add:

Address: Zhenxing North Road, Zhenwu Town, Jiangdu District, Yangzhou City, Jiangsu Province

Copyright: Yangzhou Zhengyi Testing Machinery Co., Ltd. 苏ICP备14021115号-4 Powered by:www.300.cn