PRODUCT

ZY-2000E Rubber Rotorless Vulcanizer

The ZY-2000E computerized rotorless vulcanizer adopts a computer-controlled imported temperature controller for accurate temperature control. The computer can process data in a timely manner and can perform statistics, analysis, storage and comparison, etc., humanized design, easy operation, accurate data, and optimized formula for rubber Provide accurate data. The buttons of the mouse on the computer of this vulcanizer have the same function as the buttons on the host panel, which is convenient for users to operate. The computer software interface is quite good and it is extremely convenient to use. Users can accurately measure the scorch time, positive vulcanization time, and vulcanization index. , Maximum and minimum torque, etc., is the ideal equipment for rubber industry to control the quality of rubber materials, rapid inspection and rubber extrusion research.

Sulfur change meter

1. Introduction:

The ZY-2000E rubber vulcanization analyzer adopts a computer-controlled imported temperature controller for temperature control. The computer can process data in a timely manner and can perform statistics, analysis, storage and comparison, etc., humanized design, easy operation, accurate data, and provide accurate rubber formula data. The buttons of the mouse on the computer of this vulcanizer have the same function as the buttons on the host panel, which is convenient for users to operate. The computer software interface is quite good and it is extremely convenient to use. Users can accurately measure the scorch time, positive vulcanization time, and vulcanization index. , Large and small torques, etc. It is an ideal equipment for rubber industry to control the quality of rubber materials, rapid inspection and rubber extrusion research.

ZY-2000E Rubber Vulcanometer is a new generation of mechatronics product launched by our factory. It is mainly composed of host, sensor, computer, data collector of lower computer, printer and electric chain.

Executive standard: ASTMD5289-95 ISO6502:1991 HG/T3709-2003

Provide vulcanization curve, temperature curve diagram. Single curve test, continuous test of any curve and comparison test of any curve are possible on the same interface, the data is stored in the database, and all curve data can be printed in real time or in history.

2. Technical parameters:

Executive standard: GB/T16584, ISO-6502

Cavity structure: fully enclosed

Temperature control range: normal temperature -200℃

Temperature fluctuation: ≤±0.1℃

Temperature display resolution: 0.01℃

Torque range: 0-20N.M

Torque display accuracy: 0.001 N.M

Power supply: 50HZ, ~220V±10%

Compressed air: ≥0.40Mpa

Swing frequency: 100cpm (1.7HZ)

Swing angle: ±0.5. ±1.

Torque range: (0-5N.m, 0-10N.m 0-20N.m) automatic

Ambient temperature: 0-35°C relative humidity <80%

Setting range of vulcanization time: 2-300min, t90 is in the range of 10 seconds to 5 hours.

Print content: date, time, temperature, curing curve, temperature curve, ML, MH, ts1, ts2, t10, t90, Vc1 Vc2

Dimensions: 600*700*1250mm

3. Main features:

1. This instrument adopts a truly closed cavity, and its repeatability and test data are comparable to Alpha

2. This instrument is based on a large-scale database development platform, and the temperature control device adopts software to directly control and collect and process.

3. This instrument has the functions of statistics, analysis, storage and comparison. Humanized design, easy to operate.

Fourth, the main configuration:

1. The real high-precision closed cavity structure is synchronized with American Alpha.

2. Joint venture high-precision sensor with accuracy of 0.001N.M

3. Japan NSK high-precision bearings.

4. High-performance cylinders of SDPC Group, a Sino-British joint venture.

5. Sino-foreign joint venture Delixi pneumatic components.

6. Special modules with powerful functions, the test data is synchronized with Alpha.

7. The working door automatically rises and falls.

8. The key parts of electronic components adopt military components, with reliable quality and stable performance.

9. The computer software directly controls the temperature, and the accuracy of Alpha technology reaches 0.01℃.

10. 19-inch Lenovo LCD computer, HP color printer.

11. Taiwan built SUNON cooling fan to protect electrical appliances from malfunctioning and truly worry-free.

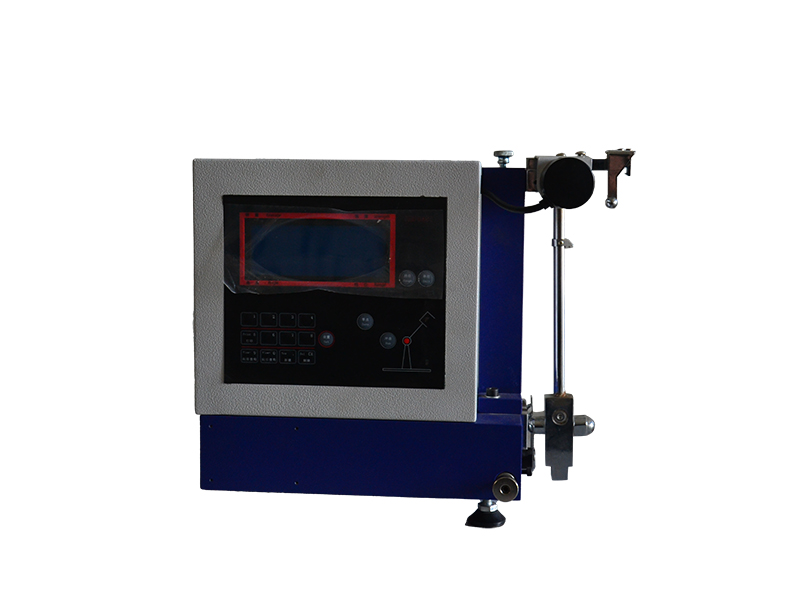

ZY-2000G Mooney Viscometer

ZY-2000G computer Mooney viscometer, measuring and temperature control circuit is composed of measuring and control module, platinum resistance, heater, can automatically track changes in the power grid and ambient temperature, automatically correct PID parameters, to achieve the purpose of rapid and accurate temperature control. The data acquisition system and electromechanical interlock complete the automatic test of the torque signal during the rubber test process, and automatically display the temperature value and set value in real time. After vulcanization, automatic processing, automatic calculation, printing Mooney, scorch curve and process parameters. The computer displays the test process in real time, and the changes of "temperature" and "time-Mooney" can be seen clearly from above. It is an indispensable instrument in the reclaimed rubber, rubber, wire and cable industries.

ZY-5000N rubber electronic tensile machine (digital display type)

ZY-5000N rubber electronic tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

The tensile machine is composed of a host, a speed control system, data acquisition and processing, sensors and electrical interlocking parts. The host includes the fuselage, transmission mechanism, and measurement system. Data processing is handled by a microcomputer processor. This machine uses a stepping speed regulator to change the stretching speed, and the speed value is directly read out. The motor moves the lower gripper (fixture) through the V-belt-worm-screw drive, so as to realize the tensile change of the sample. The head of the main unit is equipped with a tension sensor, and its upper end is connected with the connecting plate of the top beam of the main unit, and the lower end is connected with the upper clamp. The sensor is only subject to vertical tension and is not affected by torsion or directional force to ensure force measurement accuracy. Between the upper and lower grippers, the force of the sample during the test is transformed into an electrical signal through the force sensor and input into the microcomputer acquisition control system. After the test is over, it is automatically processed, automatically calculated, and the result is displayed.

The touch LCD measurement and control system adopts 32-bit ARM technology and DSP high-performance processor control technology. The display part adopts a 7-inch 65K color ultra-clear touch screen with a resolution of 1024*768. The ultra-high performance configuration makes the software function and user experience great improve. The software includes boot animation, main screen display, large curve display, unit setting, multiple test standard selection and result calculation display, equipment status display, hardware parameter setting, equipment calibration, PID parameter setting, custom parameter editing, sample plan Editing, sample size editing, visual printing and other functions, the micro printer supports a variety of models to choose from, and the motor control supports free switching of multiple control methods such as servo, stepping, frequency conversion, and DC (the factory does not need to replace the system, and the standard features).

This test measurement and control system is a high-performance measurement and control instrument designed specifically for electronic testing machines that integrates measurement and control. It can perform tensile, compression, bending, shear, tear, and peel tests. The software can complete the maximum force, maximum deformation, tensile strength, elongation at break, total elongation at maximum force, elongation at yield point, elongation after fracture, upper and lower yield strength, elastic modulus, force at yield point, and elongation at break , Calculation and real-time display of parameters such as elongation at yield point, tensile strength at break, tensile stress at yield point, constant elongation stress, constant elongation (according to user-specified constant force level) and other parameters, among which the level of constant elongation The value and the constant force level value can be entered into the relevant position of the software in the sample parameter interface according to the actual requirements of the customer. The parameters that can be calculated also include compressive strength, upper and lower compression yield strength, compression elastic modulus, bending strength, bending elastic modulus, average bending force, average peel force, peel strength, maximum peel force, minimum peel force, tear strength , Average shear force, shear strength, shear modulus and other mechanical and physical properties related parameters.

Main interface function introduction

ZY-5000N Rubber Electronic Tension Machine

ZY series electronic tensile machine can be used for rubber, plastic, foam material, plastic, film, textile, fiber, polymer material, composite material, synthetic material, packaging tape, paper, wire and cable, fiber optic cable safety belt, leather belt, shoe Types, tapes, polymers, spring steel, stainless steel, castings, non-ferrous metals, auto parts alloy materials and other non-metallic materials and metal materials for stretching, compression, bending, tearing, 90° peeling, 180° peeling, shearing Cut, adhesion, pull-out force, elongation and other tests.

Host specifications

ZY-1008 Rubber Shaving Machine

In order to cooperate with testing institutions at all levels and wire and cable manufacturers to better implement the GB/T529-2008 "General Test Methods for Wires, Cables and Sheath Materials" standard, for polymer insulation and sheath materials in the GB/T529-2008 standard Under the guidance of relevant experts from the Shanghai Cable Research Institute, the new requirements put forward by the mechanical and physical performance tests have been developed for the cable die chipper (also called the chipper). This machine adopts a series of technologies to enable the blade to be placed horizontally, replaceable and grind, and meet the requirements of the operating principle of the equipment for sample preparation in GB/T529-2008. Test personnel need to carefully read the contents of the relevant chapters of the GB/T529-2008 standard, carefully read the operating instructions of the machine, understand the use of the machine, and master the specific operating steps and precautions in order to prepare high-quality test pieces.

SQ-300 Rubber and Plastic Flaker

1. Performance and use

In order to cooperate with testing institutions at all levels and wire and cable manufacturers to better implement the GB/T2951-2008 "General Test Methods for Cable and Optical Cable Insulation and Sheath Materials" standard, for polymer insulation and sheath materials in the GB/T2951 standard Under the guidance of the relevant experts of the Cable Research Institute, the new requirements put forward by the mechanical and physical performance test, the cable die chipper (also called the chipper) was developed. This machine adopts a series of technologies to enable the blades to be placed horizontally, replaceable and grind, and meet the requirements of the operating principles of the equipment for preparing samples in GB/T 2951 and 2941. The user needs to read the manual of the machine carefully, understand the use method of the machine, master the specific operation steps and precautions, in order to be able to prepare high-quality test pieces.

This test slicer is a kind of equipment used for sampling in rubber and plastic products factories. It adopts mechanical transmission to feed material and the structure of blade cutting, which can cut various thicknesses of soft plastic, rubber sheet and rubber waterstop within the range of 1-12 mm, and can also be used for slicing some rubber and leather materials. This machine is widely used in rubber, soft plastic, leather, wire and cable manufacturers, scientific research and other units.

This machine is suitable for the matching cables and communication cables specified in the standard GB/T2951-2008 "General Test Methods for Wires, Cables and Sheath Materials", including samples for the mechanical and physical performance testing of polymer insulating sheath materials of marine cables preparation. Meet GB/T2941-2006 "Rubber Physical Sample Method, General Procedure for Sample Preparation and Adjustment".

2. Main technical specifications

Worktable width 300mm

The slice width is not more than 100mm (according to different materials, it is recommended that 25-35mm is preferred)

Slice thickness 1-12mm

Feeding thickness is not more than 20mm

Working voltage 380V

Dimensions L×W×H 500×500×1340mm

Net weight 215 kg

Three, structure and use

This slicer is composed of body, transmission, adjustment, manipulation, etc. The structure and use of each part are introduced as follows:

1. Body and transmission

The lower part of the fuselage is the machine base, the inside is equipped with electric motors and electrical accessories, the outside is equipped with motor start and stop switches, the upper part of the fuselage is the working part, equipped with left and right frames, worktables, compression shafts, feeding shafts and adjustment structures Wait.

When working, start the switch, turn on the motor, the slicer starts to run, and the stop switch stops the slicer.

The transmission is driven by a motor, which drives the transmission shaft to rotate through the main and auxiliary pulleys. The gears installed at both ends of the drive shaft respectively drive the lower and upper feed shafts to rotate, and the gears on the upper feed shaft drive the compression shaft to rotate simultaneously.

2. Manipulation and adjustment

The top operating handwheel is generally used for adjustment. This wheel is idling during work. The slice thickness is adjusted by rotating the adjustment handwheel above the frame to drive the compression shaft of the transmission system and the upper feeding shaft to rise (or fall) to the position The required slice thickness. The thickness of the handwheel is adjusted to 2 mm per turn.

ZY-003 Rubber Double-head Grinding Machine

The ZY-1003 double-head grinding machine is used by rubber factories and scientific research units to grind rubber test pieces to a certain thickness for other test equipment to test. It is one of the indispensable equipment in the inspection of rubber quality. The product has a compact structure, two types of coarse and fine grinding wheels work at the same time, with the characteristics of one machine and two purposes, easy to use, time-saving, safe and reliable.

ZY-1011K Rubber rebound impact testing machine (scale)

1. Features and uses:

This machine is an energy 0.5J pendulum impact elasticity tester, suitable for measuring the rebound value of vulcanized rubber with a hardness of 30-85IRHD. It meets the requirements of GB/T 1681 "Determination of Resilience of Vulcanized Rubber" and ISO4662 standards.

2. Technical parameters:

1. Punch diameter: 15mm

ZY-1011S Rubber rebound impact testing machine (digital display)

1. Purpose

This testing machine is an energy 0.5J pendulum impact elasticity testing machine, which is suitable for measuring the rebound value of vulcanized rubber with a hardness of 30-85 Shao A or IRHD. This machine has the characteristics of stable and reliable performance, high precision and easy use. The rebound rate can be directly calculated, and the four-screen display can display the angle or angle peak value, the rebound rate, the median value, and the count.

Calculate the median

Save the parameters of up to 1000 samples, which belong to 64 sample groups and can be queried;

Test results can be deleted;

ZY-1006 Rubber Low Temperature Brittleness Testing Machine (Single Sample)

The ZY-1006 rubber-plastic low-temperature brittleness testing machine is used to determine the highest temperature when the sample is damaged by impact under specified conditions, that is, the brittle temperature. It can be used for comparative evaluation of the performance of plastics and other elastic materials under low temperature conditions. . It can measure the brittleness temperature and low temperature performance of different rubber materials or different formulations of vulcanized rubber.

ZY-1006 Rubber Low Temperature Brittleness Testing Machine (Multi-sample Method)

The ZY-1006 rubber-plastic low-temperature brittleness testing machine is used to determine the highest temperature when the sample is damaged by impact under specified conditions, that is, the brittle temperature. It can be used for comparative evaluation of the performance of plastics and other elastic materials under low temperature conditions. . It can measure the brittleness temperature and low

ZY-1006 Plastic Low Temperature Brittleness Testing Machine

1. Features and uses:

The ZY-1006 rubber-plastic low-temperature brittleness testing machine is to measure the temperature at which the sample is damaged by impact under specified conditions, which is the brittle temperature. It can be used for comparative evaluation of the performance of plastics and other elastic materials under low-temperature conditions. It can measure the brittleness temperature and low temperature performance of different rubber materials or different formulations of vulcanized rubber. Therefore, it is indispensable in the quality inspection of scientific research materials and products, and the control of the production process. This instrument is designed according to the GB/T 5470-2008 standard. It is equipped with a B-type fixture and impact head that can test multiple samples at the same time. This test fixture can hold 5 samples for simultaneous testing.

2. Technical parameters

1. Test temperature and time: -70 degrees (normally more than 1 hour), the cooling time is short, no water cooling is needed, and it is more environmentally friendly.

2. Cooling speed:

0℃ ~ -30℃ 1.2℃/min

-30℃ ~ -40℃ 1℃/min

-40℃ ~ -70℃ 0.7℃/min

3. Impact speed: 2m/s±0.2m/s

4. After the constant temperature, the temperature fluctuation is less than ±0.5℃, and the temperature control is more accurate.

5. The distance from the midpoint of the impactor to the lower end of the holder: 8±0.5mm

6. Dimensions: 900×505×950mm (length×height×width)

7. Effective space of studio: 160×140×100mm (length×height×width)

8. Power: 2000W

Three, structure principle

1 Lifting gripper The lifting gripper is composed of a cylinder with a gripper and a cylinder block.

The distance from the impacted part of the sample to the lower end of the holder is 8.0±0.5mm.

2 Impact device The impact device is composed of an impactor and an impact cylinder.

3 impactor

The weight of the impactor is 200±20g, and its working stroke is 40±1mm. When the impact cylinder is in the reset state, the distance from the end of the impactor to the sample is 25±1mm.

4 Freezing medium: industrial ethanol

5 This measuring instrument uses a compressor for direct cooling. It does not require cooling circulating water.

Four, use method

1 Turn on the power, the temperature controller and timer display lights are on.

2 Inject the freezing medium (usually industrial ethanol) into the cold well. The injection amount should ensure that the holder sample can be immersed below 25mm of the medium liquid level.

3 Clamp the sample vertically on the holder. The clamp should not be too tight or too loose to prevent the specimen from deforming or falling off.

4 After reaching the test temperature, press the start button, and the testing machine will work automatically (press the holder to start freezing the sample, and at the same time start the timing control switch or press the stopwatch to time, the sample freezing time is specified as 3min. The sample freezing period , The temperature fluctuation of the freezing medium shall not exceed ±1℃)

5 Take off the sample and check each sample to determine whether it is damaged. The cracks, cracks, or small holes that appear during the test, or separate into two pieces so that more fragments are defined as damage, when the sample is not broken At the time, bend the specimen 90° in the bending direction formed during the impact, and then inspect the specimen for cracks at the bend.

6 After the sample is impacted (each sample can only be impacted once), if damage occurs, the temperature should be increased by 10℃ to do a new set of tests, and a new sample should be used at each temperature until the sample is not damaged. If there is no damage to the sample, then the temperature is reduced to the highest temperature of damage that has been observed. Control the temperature increase or decrease at a temperature interval of 2°C until the temperature at which a set of samples is not damaged is measured, and this temperature is recorded as the brittle temperature.

5. Sample standard

1 Specification requirements: length 31.75±6.35mm, width 6.35±0.51mm, thickness 1.91±0.13mm

2 Requirements: The surface of the sample should be smooth, free of foreign impurities and damage. The finished product should be cut into corresponding size after grinding.

Six, matters needing attention

The cylinder pressure has been adjusted before leaving the factory and cannot be changed arbitrarily.

401-A hot air aging test box (200 degrees)

This machine is used for thermal oxygen aging test of rubber, plastic, wire and cable, electrical insulation material and other materials. Digital display temperature control can be used for hot air aging test of rubber and plastic products, electrical insulation and other materials. The temperature control adopts digital display and PID automatic temperature controller.

401-A hot air aging test box (300 degrees)

This test box is used for thermal oxygen aging test of rubber, plastic, wire and cable, electrical insulation materials and other materials. Digital display temperature control can be used for hot air aging test of rubber and plastic products, electrical insulation and other materials. The temperature control adopts digital display and PID automatic temperature controller. The working temperature can be set arbitrarily from room temperature to 300℃.

ZY-100 Ozone Aging Test Chamber (Static)

This equipment is mainly suitable for the ozone aging resistance test of polymer materials and their products. The amount of ozone in the atmosphere is the main factor in the aging of polymer materials and products. The ozone aging box can simulate and strengthen the ozone conditions in the atmosphere. Obtain test results similar to actual use or reproducibility in a short time, study the effect of ozone on polymer materials and their products (rubber), and quickly identify and evaluate rubber anti-ozone aging performance and anti-ozone agent protective efficacy methods , And then take effective anti-aging measures to improve the service life of rubber products.

ZY-100 Ozone Aging Test Chamber (Dynamic)

This equipment is mainly suitable for the ozone aging resistance test of polymer materials and their products. The amount of ozone in the atmosphere is the main factor in the aging of polymer materials and products. The ozone aging box can simulate and strengthen the ozone conditions in the atmosphere. Obtain test results similar to actual use or reproducibility in a short time, study the effect of ozone on polymer materials and their products (rubber), and quickly identify and evaluate rubber anti-ozone aging performance and anti-ozone agent protective efficacy methods , And then take effective anti-aging measures to improve the service life of rubber products.

25T Flat Vulcanizing Press

The plate vulcanizing machine is a new type of hydraulic plate vulcanizing machine, which can improve the quality of the pressed parts and greatly increase the labor productivity compared with the old type of pressure forming machine. This model is suitable for the vulcanization of various rubber products. It is a necessary equipment for the molding and processing of plastic, rubber foam, bakelite products, and various thermosetting materials. This model has the following characteristics:

25T flat vulcanizing machine (water cooling)

The plate vulcanizing machine is a new type of hydraulic plate vulcanizing machine, which can improve the quality of the pressed parts and greatly increase the labor productivity compared with the old type of pressure forming machine. This model is suitable for the vulcanization of various rubber products. It is a necessary equipment for the molding and processing of plastic, rubber foam, bakelite products, and various thermosetting materials. This model has the following characteristics:

XK-160 open mixing mill

The main technical parameters

1. Roller diameter: 160mm

2. Roller surface width: 320mm

3. Speed ratio of front and rear rollers: 1:1.35

4. Front roller linear speed: 8.3m/min 17.85 revolutions per minute

XK-160 open mixer (electric heating)

XK-160 open mixer (6 inch electric heating)

The main technical parameters

1. Roller diameter: 160mm

2. Roller surface width: 320mm

3. Speed ratio of front and rear rollers: 1:1.35

ZY-1002 Rubber Akron Abrasion Machine

I. Overview

The rubber Akron abrasion machine is used to determine the wear resistance of vulcanized rubber. The sample is rubbed with the grinding wheel under a certain inclination angle and a certain load to determine the abrasion volume of the sample within a certain mileage. It meets the requirements of GB/T 1689 "Determination of Abrasion Resistance of Vulcanized Rubber" and other standards. Digital setting, display of wear times, automatic shutdown, the host computer and electrical control are designed as a whole, the use of calibrated grinding wheel, beautiful appearance, easy to operate.

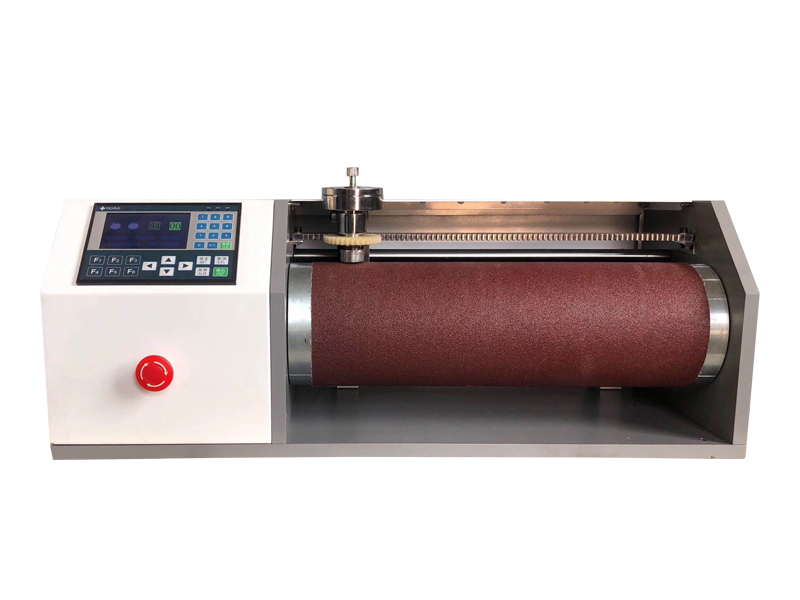

ZY-1001 Rubber Roller Abrasion Machine

The ZY-1001 roller abrasion machine is developed with reference to the standard ISO 4649 "Measurement of the wear resistance of rubber with a rotating roller device" and the standard GB 9867 "Determination of the wear resistance of vulcanized rubber (rotating roller abrasion machine method)" . Compared with the commonly used Akron Abrasion Tester and Grassili Abrasion Tester, this machine has the advantages of small sample required, short test period and non-repetitive friction path. It is currently a more general-purpose abrasion tester. The machine is mainly composed of a power system, a rotating roller, a sample holder, an automatic shutdown system, a rack and pinion gear device for sample rotation, a base, and a dust collector. The main principle is: under a certain load, on a certain level of gauze, the cylindrical sample is cross-cut and ground on the surface of the gauze for a certain stroke, and the mass wear of the sample is measured, and then the density of the sample is calculated Volume wear. In order to make the test comparable, it is necessary to use standard rubber, and express the test result as the relative volume wear based on the calibrated gauze or as the wear resistance base relative to the wear of a certain standard rubber.

Previous page

1

2

Next page

Yangzhou Zhengyi Testing Machinery Co., Ltd.

Service Hotline:

Add:

Address: Zhenxing North Road, Zhenwu Town, Jiangdu District, Yangzhou City, Jiangsu Province

Copyright: Yangzhou Zhengyi Testing Machinery Co., Ltd. 苏ICP备14021115号-4 Powered by:www.300.cn