Number of views:

1000

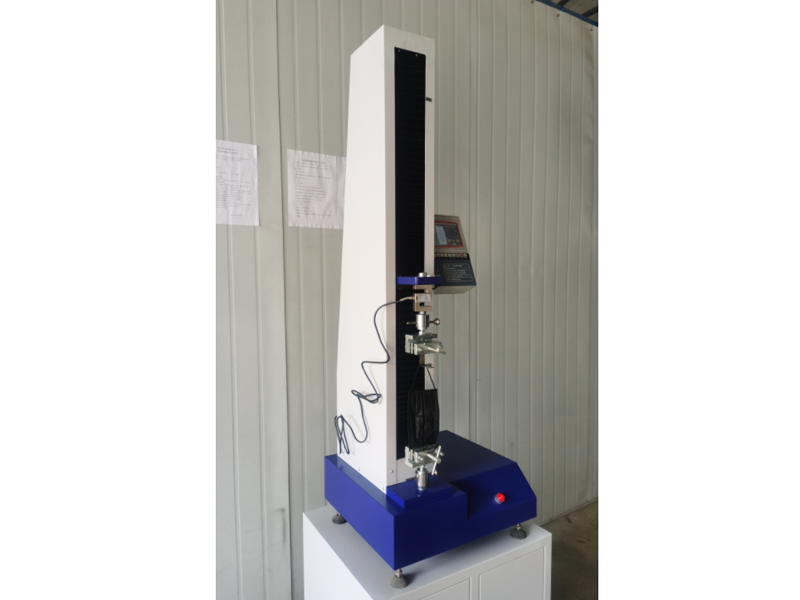

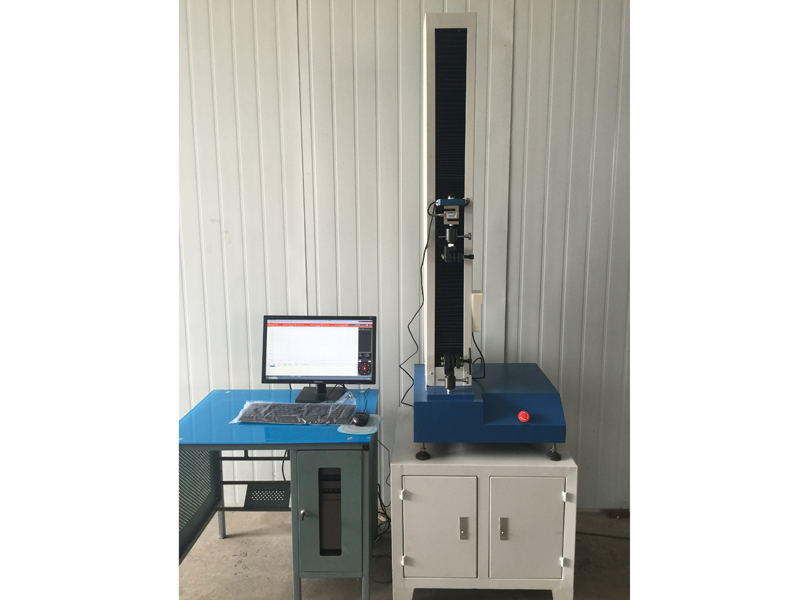

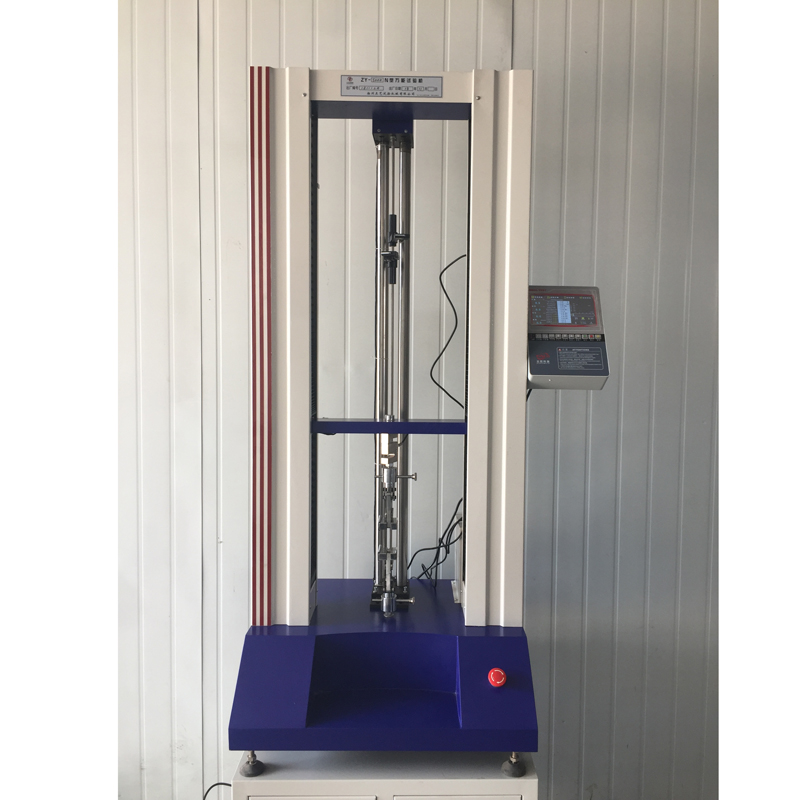

ZY-50kN pipe ring stiffness testing machine

Retail price

0.0

元

Market price

0.0

元

Number of views:

1000

Product serial number

045

Quantity

-

+

Stock:

0

Product description

Parameters

1. Product introduction:

The microcomputer control ring stiffness testing machine is easy to operate and has stable and reliable performance. The system uses a high-precision controller and a speed control system to control the rotation of the servo motor. After the deceleration system is decelerated, the beam is driven up and down by the precision ball screw pair to complete the tensile mechanical performance test of the sample. It is pollution-free, low noise, and efficient. High, with a wide speed range. Comply with the design basis of this machine: "GB/T9647-2003 Thermoplastic Pipe Ring Stiffness Determination", GB/T18477-2001 "Unplasticized Polyvinyl Chloride (PVC-U) Double Wall Corrugated Pipe for Buried Drainage"; GB/T18998. 2-2003 "Industrial Chlorinated Polyvinyl Chloride (PVC-C) Piping System Part 2: Pipes" GB/T9647-2003 "Determination of Ring Stiffness of Thermoplastic Pipes" requirements. This machine is widely used in material inspection and analysis in steel metallurgy, building materials, aerospace, machinery manufacturing, wire and cable, rubber and plastic, textile, home appliances and other industries. It is used for scientific research institutions, universities, industrial and mining enterprises, technical supervision, and commodity inspection arbitration. The ideal test equipment for departments.

The pipe ring stiffness testing machine adopts a fully digital servo speed control system with high speed control accuracy and stable performance and a servo motor as the drive system. The precision controller is the core of the control system. The control and data processing software with WINDOWS as the operation interface realizes the test force. , Test force peak value, beam displacement, test deformation and test curve screen display, all test operations can be automatically completed on the computer through the mouse. Good humanized design makes the test operation easier.

2. Main technical indicators:

1. Test force: 50kN

2. Measuring range: 2%—99% of the maximum test force (0.4%—99%)

3. Accuracy level of testing machine: Class I

4. Test force accuracy: better than ±1% of the indicated value

5. Beam displacement measurement: resolution is 0.001mm

6. Deformation accuracy: better than ±1%

7. Speed adjustment range: 1-300mm/min

8. Test space: 800mm up and down, width>350mm

9. Host form: portal frame structure

10. Host size: 730*590*1850mm

11. Weight: about 350Kg

12. Working environment: room temperature~45℃, humidity 20%~80%

3. Main functions and features:

1. Host:

1.1 The machine adopts a portal space structure; downward pressure.

1.2 The speed control system adopts servo motor and speed governor, with stable and reliable performance, and has protection devices such as overcurrent, overvoltage, and overload. The speed range can reach 1~200mm/min.

1.3 The transmission part adopts circular arc synchronous toothed belt, precision screw pair transmission, stable transmission, low noise and high transmission efficiency.

2. Control system, operating software and data processing system

2.1 The computer control system has the advantages of high integration, stable performance and convenient adjustment. The experimental data can be collected in real time, and the experimental characteristic curve can be displayed dynamically in real time. The experimental data files can be saved in Access common databases or SQLserve large databases, which facilitates the realization of customer resource sharing and network management, as well as user re-analysis. For user-defined various word2000 reports, the software can be easily accessed, which solves the problem that different users or the same user have different needs for test reports in different periods. The software can process the original data of test force, displacement, time, deformation and curves derived therefrom.

2.2 Protection function: The machine has two limit protection modes, software and mechanical, and the proportion of automatic shutdown when the maximum load is exceeded can be dynamically set; it has multiple protection functions such as overcurrent, overvoltage, and overload.

2.3 The load and deformation channels can be automatically marked, which is intuitive and convenient.

2.4 The batch test can realize the hierarchical display of the curve, and the curve automatically follows.

2.5 The software can realize user-defined speed setting and computer adjustment of speed. It can also achieve high-precision speed calibration, and adjust the speed gear and code at any time.

2.6 Monitoring the test process: Real-time display of various parameters such as test force, deformation, displacement, and curve during the test process.

2.7 Software authority classification management function: In order to improve the security of software and data, the software can realize the function of authority management by setting different password protection.

2.8 Result reproduction function: After the test operation is completed and saved, it can be opened and re-analyzed at any time in the future according to user needs.

2.9 According to user needs, select load-deformation, load-time, load-displacement, displacement-time, deformation-time and other curves for testing and data display, storage, analysis and printing.

2.10 Curve point-by-point traversal function: You can click the force and deformation values on the curve with the mouse to obtain various parameters of each point.

2.11 Result comparison function: You can observe multiple test curves at the same time, and compare the characteristics of the samples to be analyzed through the superposition and partial amplification of multiple curves.

2.12 Force interface: Force channel interface and test software can be equipped with various sensors according to user needs, and can be calibrated, modified parameters and normal tests.

2.13 Deformation interface: Deformation channel interface and test software can be equipped with various types of extensometers according to user needs, and can be calibrated, modified parameters and normal tests.

2.14 Data sampling frequency: High-speed sampling frequency can be selected according to user test requirements.

Special accessories: In addition to standard accessories, special accessories can also be equipped according to user needs.

Four, basic configuration

1. Test machine host 1 set

2. Servo motor 1 set

3. 1 set of speed control system

4. Load sensor 1

5. 2 sets of precision lead screws

6. Deceleration system 1 set

7. 1 set of full digital control system

8. 1 Lenovo LCD computer

9. 1 HP inkjet printer

10. Computer control software 1 set

11. Compression accessory 1 set

Previous

None

Next

None

Recommended Products

ZY-2000E Rubber Rotorless Vulcanizer

The ZY-2000E computerized rotorless vulcanizer adopts a computer-controlled imported temperature controller for accurate temperature control. The computer can process data in a timely manner and can perform statistics, analysis, storage and comparison, etc., humanized design, easy operation, accurate data, and optimized formula for rubber Provide accurate data. The buttons of the mouse on the computer of this vulcanizer have the same function as the buttons on the host panel, which is convenient for users to operate. The computer software interface is quite good and it is extremely convenient to use. Users can accurately measure the scorch time, positive vulcanization time, and vulcanization index. , Maximum and minimum torque, etc., is the ideal equipment for rubber industry to control the quality of rubber materials, rapid inspection and rubber extrusion research.

Sulfur change meter

1. Introduction:

The ZY-2000E rubber vulcanization analyzer adopts a computer-controlled imported temperature controller for temperature control. The computer can process data in a timely manner and can perform statistics, analysis, storage and comparison, etc., humanized design, easy operation, accurate data, and provide accurate rubber formula data. The buttons of the mouse on the computer of this vulcanizer have the same function as the buttons on the host panel, which is convenient for users to operate. The computer software interface is quite good and it is extremely convenient to use. Users can accurately measure the scorch time, positive vulcanization time, and vulcanization index. , Large and small torques, etc. It is an ideal equipment for rubber industry to control the quality of rubber materials, rapid inspection and rubber extrusion research.

ZY-2000E Rubber Vulcanometer is a new generation of mechatronics product launched by our factory. It is mainly composed of host, sensor, computer, data collector of lower computer, printer and electric chain.

Executive standard: ASTMD5289-95 ISO6502:1991 HG/T3709-2003

Provide vulcanization curve, temperature curve diagram. Single curve test, continuous test of any curve and comparison test of any curve are possible on the same interface, the data is stored in the database, and all curve data can be printed in real time or in history.

2. Technical parameters:

Executive standard: GB/T16584, ISO-6502

Cavity structure: fully enclosed

Temperature control range: normal temperature -200℃

Temperature fluctuation: ≤±0.1℃

Temperature display resolution: 0.01℃

Torque range: 0-20N.M

Torque display accuracy: 0.001 N.M

Power supply: 50HZ, ~220V±10%

Compressed air: ≥0.40Mpa

Swing frequency: 100cpm (1.7HZ)

Swing angle: ±0.5. ±1.

Torque range: (0-5N.m, 0-10N.m 0-20N.m) automatic

Ambient temperature: 0-35°C relative humidity <80%

Setting range of vulcanization time: 2-300min, t90 is in the range of 10 seconds to 5 hours.

Print content: date, time, temperature, curing curve, temperature curve, ML, MH, ts1, ts2, t10, t90, Vc1 Vc2

Dimensions: 600*700*1250mm

3. Main features:

1. This instrument adopts a truly closed cavity, and its repeatability and test data are comparable to Alpha

2. This instrument is based on a large-scale database development platform, and the temperature control device adopts software to directly control and collect and process.

3. This instrument has the functions of statistics, analysis, storage and comparison. Humanized design, easy to operate.

Fourth, the main configuration:

1. The real high-precision closed cavity structure is synchronized with American Alpha.

2. Joint venture high-precision sensor with accuracy of 0.001N.M

3. Japan NSK high-precision bearings.

4. High-performance cylinders of SDPC Group, a Sino-British joint venture.

5. Sino-foreign joint venture Delixi pneumatic components.

6. Special modules with powerful functions, the test data is synchronized with Alpha.

7. The working door automatically rises and falls.

8. The key parts of electronic components adopt military components, with reliable quality and stable performance.

9. The computer software directly controls the temperature, and the accuracy of Alpha technology reaches 0.01℃.

10. 19-inch Lenovo LCD computer, HP color printer.

11. Taiwan built SUNON cooling fan to protect electrical appliances from malfunctioning and truly worry-free.

ZY-2000G Mooney Viscometer

ZY-2000G computer Mooney viscometer, measuring and temperature control circuit is composed of measuring and control module, platinum resistance, heater, can automatically track changes in the power grid and ambient temperature, automatically correct PID parameters, to achieve the purpose of rapid and accurate temperature control. The data acquisition system and electromechanical interlock complete the automatic test of the torque signal during the rubber test process, and automatically display the temperature value and set value in real time. After vulcanization, automatic processing, automatic calculation, printing Mooney, scorch curve and process parameters. The computer displays the test process in real time, and the changes of "temperature" and "time-Mooney" can be seen clearly from above. It is an indispensable instrument in the reclaimed rubber, rubber, wire and cable industries.

ZY-5000N rubber electronic tensile machine (digital display type)

ZY-5000N rubber electronic tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

The tensile machine is composed of a host, a speed control system, data acquisition and processing, sensors and electrical interlocking parts. The host includes the fuselage, transmission mechanism, and measurement system. Data processing is handled by a microcomputer processor. This machine uses a stepping speed regulator to change the stretching speed, and the speed value is directly read out. The motor moves the lower gripper (fixture) through the V-belt-worm-screw drive, so as to realize the tensile change of the sample. The head of the main unit is equipped with a tension sensor, and its upper end is connected with the connecting plate of the top beam of the main unit, and the lower end is connected with the upper clamp. The sensor is only subject to vertical tension and is not affected by torsion or directional force to ensure force measurement accuracy. Between the upper and lower grippers, the force of the sample during the test is transformed into an electrical signal through the force sensor and input into the microcomputer acquisition control system. After the test is over, it is automatically processed, automatically calculated, and the result is displayed.

The touch LCD measurement and control system adopts 32-bit ARM technology and DSP high-performance processor control technology. The display part adopts a 7-inch 65K color ultra-clear touch screen with a resolution of 1024*768. The ultra-high performance configuration makes the software function and user experience great improve. The software includes boot animation, main screen display, large curve display, unit setting, multiple test standard selection and result calculation display, equipment status display, hardware parameter setting, equipment calibration, PID parameter setting, custom parameter editing, sample plan Editing, sample size editing, visual printing and other functions, the micro printer supports a variety of models to choose from, and the motor control supports free switching of multiple control methods such as servo, stepping, frequency conversion, and DC (the factory does not need to replace the system, and the standard features).

This test measurement and control system is a high-performance measurement and control instrument designed specifically for electronic testing machines that integrates measurement and control. It can perform tensile, compression, bending, shear, tear, and peel tests. The software can complete the maximum force, maximum deformation, tensile strength, elongation at break, total elongation at maximum force, elongation at yield point, elongation after fracture, upper and lower yield strength, elastic modulus, force at yield point, and elongation at break , Calculation and real-time display of parameters such as elongation at yield point, tensile strength at break, tensile stress at yield point, constant elongation stress, constant elongation (according to user-specified constant force level) and other parameters, among which the level of constant elongation The value and the constant force level value can be entered into the relevant position of the software in the sample parameter interface according to the actual requirements of the customer. The parameters that can be calculated also include compressive strength, upper and lower compression yield strength, compression elastic modulus, bending strength, bending elastic modulus, average bending force, average peel force, peel strength, maximum peel force, minimum peel force, tear strength , Average shear force, shear strength, shear modulus and other mechanical and physical properties related parameters.

Main interface function introduction

ZY-5000N Rubber Electronic Tension Machine

ZY series electronic tensile machine can be used for rubber, plastic, foam material, plastic, film, textile, fiber, polymer material, composite material, synthetic material, packaging tape, paper, wire and cable, fiber optic cable safety belt, leather belt, shoe Types, tapes, polymers, spring steel, stainless steel, castings, non-ferrous metals, auto parts alloy materials and other non-metallic materials and metal materials for stretching, compression, bending, tearing, 90° peeling, 180° peeling, shearing Cut, adhesion, pull-out force, elongation and other tests.

Host specifications

ZY-500N Mask Tensile Machine

The ZY-500N mask tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

ZY-500N Mask Tensile Machine

The ZY series mask tensile machine is used to measure the tensile properties of various masks.

The appearance of this machine is novel and generous. Computer digital speed control system, equipped with force sensor and automatic elongation tracking device, good stability. Electrical appliances use PC and interface circuit boards to collect, store, process and print test results. The maximum force, yield force, average peel force, maximum deformation and other basic physical properties of the material can be calculated. During the test, the microcomputer collects the force value and deformation signal in real time, and the software displays the "force value-displacement" curve. After the test, it automatically calculates and saves the parameters, and can print out the report form the user needs.

2. Structural principle

The host is composed of an electronic speed regulation system, a transmission mechanism, a force measurement system and an extension automatic tracking device.

Electronic speed control system: The machine adopts AC speed control, corresponding to the stretching speed of 1-Xmm/min (X is the user's bottom request), and returns at high speed.

Elongation tracking device: This device is used to measure the deformation of the sample. It can be tracked by an external tracker or a built-in tracker. It can also be tracked by the deformation device built in the motor without the tracker.

3. Main technical parameters

1. Force resolution: 0.001-0.1N

2. System accuracy: less than ±0.1

3. Maximum test force: 500N

4. Accuracy level: 0.5

5. Test force measurement range: 1-99%

6. Test force indication error: less than or equal to 0.3%

7. Test force resolution: 0.001

8. Displacement resolution: 0.001

9. Displacement indication error: less than or equal to 0.5%

10. Speed range: 0-500mm/min (special requirements can be customized)

11. Large stroke of gripper: 800mm

12. Elongation tracking error: ±0.1mm

13. Power supply voltage: AC220V±10% 50Hz

14. Net weight: 120KG

Four, characteristics

Automatic clearing: After the computer controls the test command, the system automatically clears;

High intelligence: After the test, the fracture is automatically judged and the fixture automatically returns to the initial position

Multi-function: different fixtures can be replaced to carry out different tests;

Automatic shift: switch to different grades according to the size of the load;

Change speed: the test speed can be changed arbitrarily

Control method: Test methods such as test force, test speed, displacement and strain can be selected.

Powerful: Record test data throughout the process. Provides functional services such as saving, comparison and tracking. The mouse can be used to arbitrarily find out the point-by-point force value and deformation data analysis of the test curve, and it can be partially enlarged and compared.

Multiple protection: with automatic limit and automatic overload protection.

Automatic calculation: automatically calculate various test results, and can modify the report arbitrarily

Automatic length measurement: equipped with a high-precision encoder, automatically measuring the displacement stroke and elongation between punctuation.

High taste: finely crafted, smooth lines, coupled with high-precision software and hardware technology and integration capabilities, reflecting the exquisite manufacturing technology and dexterity.

Five, configuration

1. Single column type.

2. One high-precision sensor

3. Japan Omron high-precision photoelectric automatic tracker

4. The testing machine software has functions of automatic calculation, storage, comparison, etc.

5. High precision control drive system

6. High precision closed loop motor

7. German Thomson ball screw

8. Synchronous belt wheel transmission, no noise, no vibration, stable operation

9. 1 special test fixture

10. 19-inch Lenovo LCD computer, HP color printer.

ZY-5000N plastic electronic tensile machine (double column digital display)

ZY-5000N plastic electronic tensile machine is an instrument used to test the mechanical properties of materials such as stretching, peeling, tearing, and H extraction. It is widely used in rubber, plastic, textile, chemical, steel wire, hose tape, wire and cable, plastic, pipe and other industries. It is a high-precision, economical and practical instrument.

News

Yangzhou Zhengyi Testing Machinery Co., Ltd.

Service Hotline:

Add:

Address: Zhenxing North Road, Zhenwu Town, Jiangdu District, Yangzhou City, Jiangsu Province

Copyright: Yangzhou Zhengyi Testing Machinery Co., Ltd. 苏ICP备14021115号-4 Powered by:www.300.cn